Technical details

- Propellant – Czech Aerosol normally uses propane butane mixtures at 2.7 and 1.2 bar pressures, DME and others. Filling with other propellants is possible upon request.

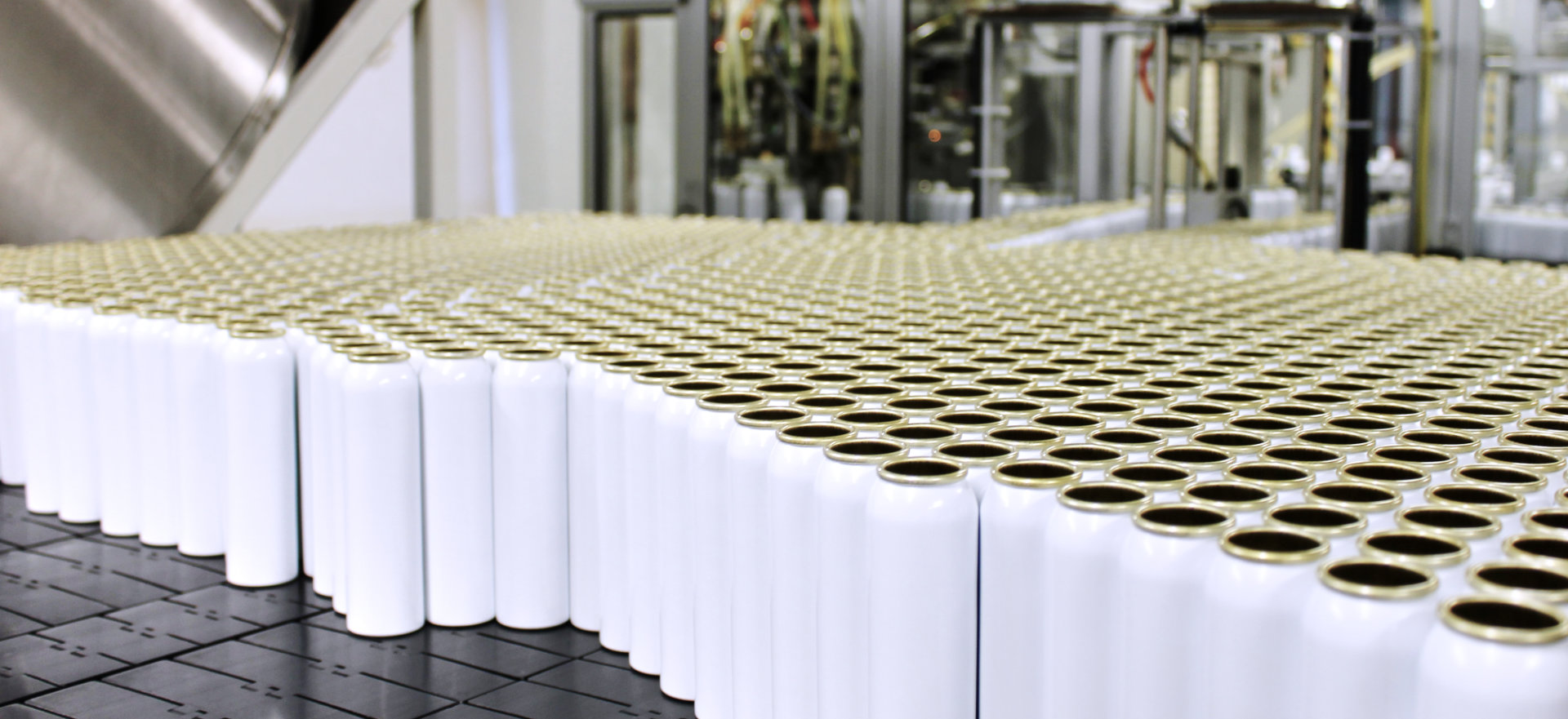

- Cans – both ALU and Tin plate cans from leading European suppliers are used for manufacturing at Czech Aerosol. All cans with diameter 35-66mm conform to FEA standards and are either fully printed or labeled.

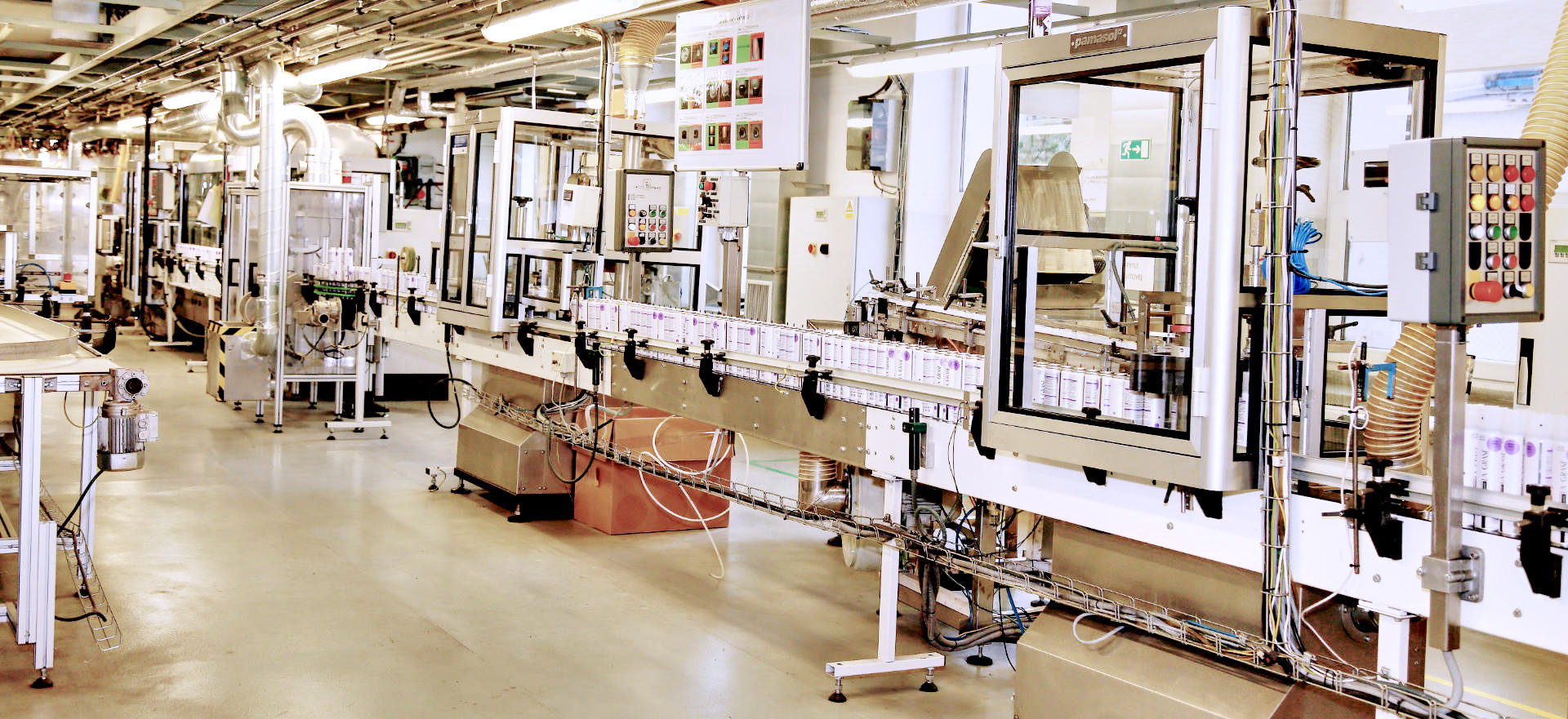

- Production lines – At Czech Aerosol, all three aerosol production lines are Swiss Pamasol made with dedicated mixing vessels and pipe-lines. Annual capacity of all three lines is around 50 million units.

- Mixing Area – Czech Aerosol uses ten mixing and storage boilers with capacities of 1,000 – 2,500l, controlled by a central computer. More mobile self-circulation boilers with capacities of 700l are also available.

Production lines

Production lines

Production lines

Production lines

Production lines

Mixing Area

Mixing Area

Mixing Area

Laboratory

Laboratory

Laboratory

Laboratory